Acorn Plasma CNC THC Control

€799,00

Op voorraad

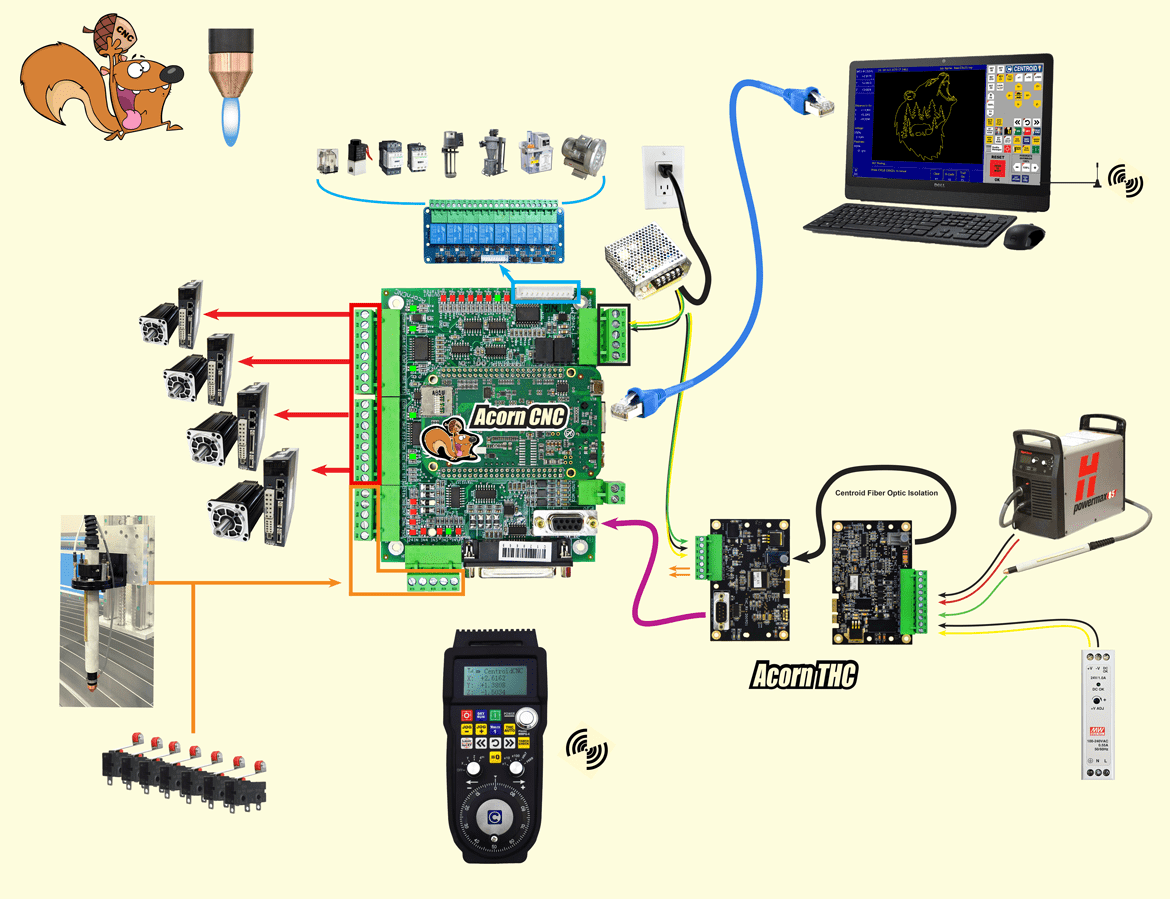

Acorn Plasma CNC THC Control: a closed loop DIY Torch Height Controller (THC) kit

Acorn Plasma CNC THC control kits are both a CNC Hardware and CNC Software DIY system designed to work together for easy CNC setup and operation with minimal fuss.

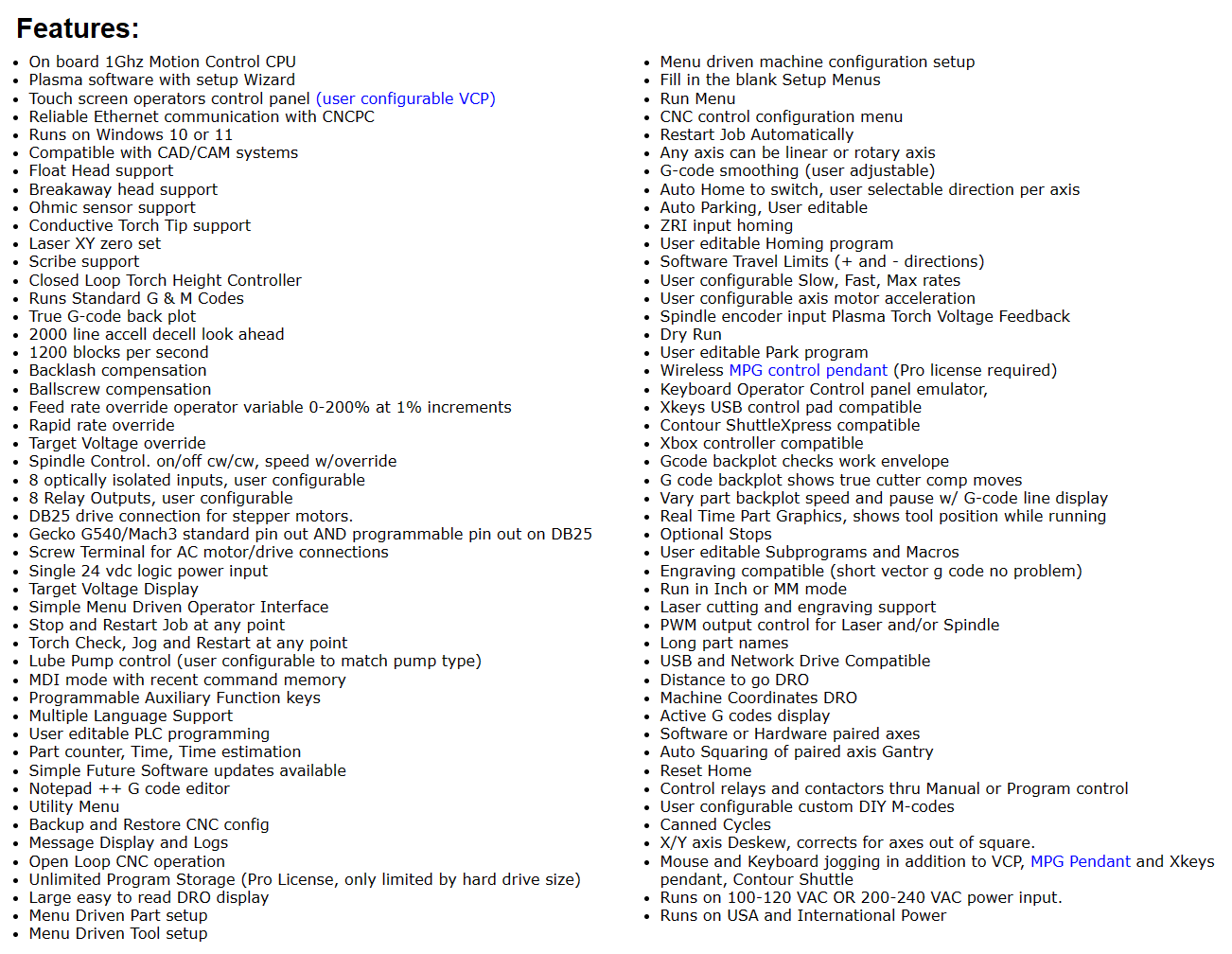

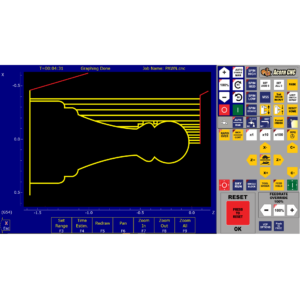

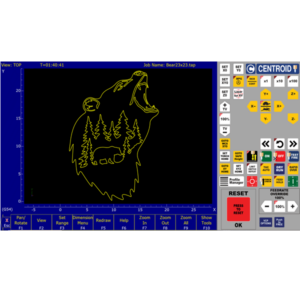

A reliable, high performance, industrial quality Plasma CNC controller with a real time closed loop Torch Height Control at a do-it-yourself price. Acorn utilizes an integrated 1Ghz ARM Cortex A8 Motion Control CPU and communicates with CNCPC via a fast and reliable Ethernet connection. The Acorn CNC control board controls a wide variety of axis motors and drives with industry standard step and direction command signal. Compatible with AC brushless servo motor drive packages such as: Clearpath, Delta, Estun, Yaskawa, and many others as well as Stepper motor drives such as the popular Gecko and Leadshine stepper drives and many others. The Acorn CNC controller runs on Centroid’s proven industrial quality CNC control software.

Centroid announces that now our Plasma THC is now compatible with the PrimeWeld Cut 60 and the Everlast i and s series CNC plasma cutters (in addition to Hypertherm, Lincoln, and Thermal Dynamics). Centroid is now offering a Plasma CNC and THC kit for the Cut 60 and the Everlast units. Available now for purchase below.

Centroid Acorn THC controller kit (part # 15149, 15321, 15322) includes:

- 1x THC TX control board

- 1x THC RX control board

- 1x 5′ Fiber Optic Cable (TX to RX connection)

- 1x 12″ Shielded Serial Cable M/F Straight ( RX-to-Acorn connection)

- 1x Din Rail Mount 24 volt power supply

Centroid’s Torch Height Controller closes the loop between Plasma Arc Voltage and Torch Height via high-speed fiber optic communication.

The Centroid Acorn THC kit provides real-time closed loop operation between the arc voltage and the torch height. The THC reads the arc voltage and sends that information to the Acorn controller via fiber optic isolation to Acorn’s high-speed encoder port.

Requirements:

– Acorn CNC controller kit (Acorn requirements are here)

– An Acorn CNC12 Plasma Pro software license

- Acorn “Start Here” Web Page with requirements and How-to Videos.

- All Acorn Documentation(a list of All Acorn related documentation)

- Acorn CNC controller Hookup Schematics(type in “Plasma” in the search bar on this page to see all Acorn Plasma hookup schematics)

- Acorn CNC Plasma Installation Manual

- Acorn Hardware and Software Installation manual.

- Plasma CNC12 software download.(Note: CNC12 installation instructions are in the Acorn Installation Manual

- Plasma Intercon Download 5.0 version here.

- Centroid CNC control board Solid Models

- Acorn Control Panel options

- Centroid CNC Community Plasma Tech Support Forum (Free Tech Support!)

- Acorn CNC controller buyers FAQ

- Acorn Warranty Info

- CNCPC Requirements

Gerelateerde producten

Acorn Lathe CNC Software License Upgrade

Op voorraad

€175,00 - €399,00Prijsklasse: €175,00 tot €399,00Acorn Plasma CNC Software License Upgrade

Op voorraad

€175,00 - €399,00Prijsklasse: €175,00 tot €399,00